Full Line of Reliable Services

We understand our clients’ different needs, so we give them answers that will streamline operations and improve workflow. Our team at Carr Manufacturing guarantees finished products that offer top-grade performance to guarantee it does the job you expect.

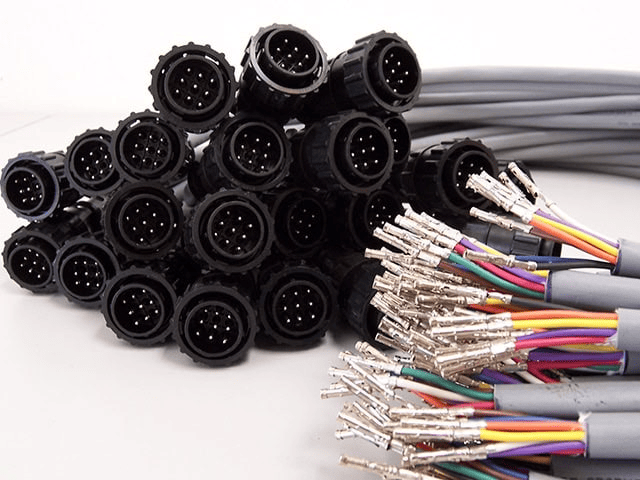

Our cable harness fabrication is done in our in-house facility that’s fully-equipped with cutting-edge technology. In addition, we follow a stringent quality control process during manufacturing to achieve unparalleled results.

Our list of services is as follows:

Cost Reduction Assistance

Cost reduction refers to identifying potential savings that can be made by reducing the cost of products without sacrificing quality. We strive to help our clients identify where they can save money while manufacturing and delivering wire harnesses on time. It aims to eliminate unnecessary expenditures that you don’t need without compromising the value you receive.

How we help with cost reduction:

- Define the needs of your project

- Assess the potential of reducing costs

- Pinpoint areas that offer reduction opportunities

It’s our job to help you maximize your profits and develop products that will save you money but won’t risk your safety. Our extensive knowledge in every industry allows us to find loopholes, increasing the value you get for the product you need.

Prototype and Engineering support

Do you have an existing design or idea? Are you looking for engineers who can turn these concepts into reality? Look no further because our experienced engineers can help you bring your designs to life. Our engineering support can build prototypes while validating and testing them to determine if they function as intended.

Prototyping is an experimental process where we study your blueprints. From there, we build it digitally and see if anything needs to be changed. To ensure the design’s integrity, we create the prototype in varying design concepts to test on users. Afterward, we work with designers so that they can make necessary changes and refinements or changes in directions, especially if client feedback or market trends dictate such.

Design Assistance

Our design assistance includes a full range of services, from creating cable assemblies drawings according to your requirements to working with our engineering team for testing. We’ll work with you throughout the process, paying attention to every detail you need and the specifications we must meet.

Some factors we consider upon designing your cable assembly:

- Environmental conditions

- Wire specifications

- Mechanical properties

- Materials required

These factors are essential to create an optimal design tailored to your unique project needs. These will dictate how your wire harness will look and function.

High volume

For high-volume or large-scale production, Carr Manufacturing can provide quick turnaround times while remaining consistent with all products we manufacture. We can produce wire and cable assemblies for standard or custom projects and high-volume orders. Additionally, all products are guaranteed to pass all industry standards.

We’ll provide the same quality product regardless of whether it’s a small or large order, so you know that you always receive the same top-grade performance. We have an excellent track record and do our best to deliver on time and within the expected deadline.

ASIA onshoring

Are you looking to relocate your manufacturing process here from Asia? We can assist you with this since our manufacturing facility has all the innovative and state-of-the-art equipment and machines to produce cable assembly and wire harness solutions you can rely on.

Onshoring is a better option for a more sustainable outcome. In addition, we can provide you with more personal attention and communication, giving you the best customer service for your needs.

Other benefits of onshoring:

- Reduced transit time for raw and finished products

- Better quality materials

- More localized customer service

- Eliminate surpluses

Choosing us as your onshore manufacturing company will provide a more cost-effective solution that guarantees superior quality control. We nurture our partnership by delivering precise and accurate outcomes each time.

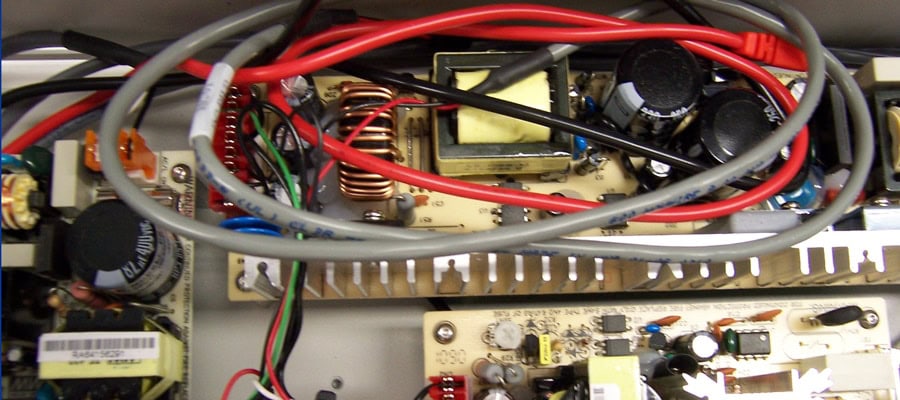

RoHS conversion

We bring your inventory into compliance with our science-backed and trustworthy RoHS conversion services. It’s the most cost-effective way to convert non-RoHS-compliant parts into fully compliant based on RoHS standards.

We achieve this by following the process below:

- Change existing Bill of Materials into RoHS-compliant materials

- Cross-reference obsolete parts into RoHS components

- Help your design team improve RoHS manufacturability

- We utilize our RoHS-compliant equipment

- Build RoHS prototypes

Using our turnkey RoHS conversion, we can quickly help you move from non-RoHS parts and components to fully compliant products.

Complete Turnkey

Let us handle all the dirty work with our full-service manufacturing services. We offer turnkey solutions so you can run your business while we handle all manufacturing and supply chain services.

What we offer:

- Engineering

- Design

- Installation

- Aftermarket support

- Technical services

Giving us full access to your manufacturing process, our team of experts will work tirelessly to ensure quality and compliance throughout the manufacturing cycle. Our turnkey solutions offer a comprehensive one-stop shop for all your manufacturing needs.

J.I.T., S.P.C., Kanban, and Vendor Managed Inventory (V.M.I.) services

We specialize in J.I.T., S.P.C., Kanban, and Vendor Managed Inventory services, which are elements required in manufacturing to streamline production and inventory while enhancing overall efficiency.

J.I.T. (Just-in-time) is a method that manufactures items when needed instead of stocking ahead of time to ensure you receive the products on time without delays or stockpiling. Kanban is an inventory control system used in J.I.T. to track production and order parts and materials as needed efficiently.

S.P.C. (Statistical Process Control) is a quality control system that monitors processes to reduce product defects. Finally, our V.M.I. services allow us to optimize inventory in your premises.

Let Us Deliver Quality Cable Assembly and Wire Harness Services

Our cable harness fabrication and specialized services allow us to produce high-performance products to improve your bottom line. From prototyping applications to managing your inventory, we provide support that will multiply your profits and give you the best experiences.

If you want to know more about our services and what we can offer, feel free to contact us today. Request a quote, and our team will develop a solution based on your needs.