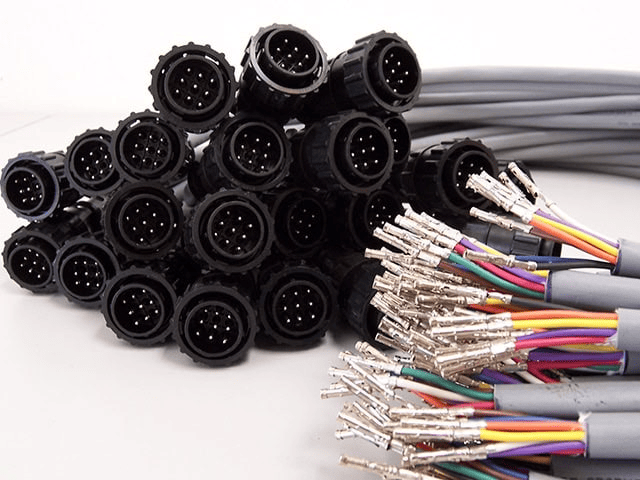

Carr Manufacturing is proud to be a woman-owned custom wire harness manufacturer and one of the leading wire harness assembly companies. We provide fully customized wire harness assembly manufacturing for all applications.

Carr Manufacturing Offers Custom Wire Harness Assembly

Carr Manufacturing has specialized in flexible, custom wire harness assembly for nearly a decade. Our approach is built on collaboration and adaptability, ensuring each project receives the attention it deserves. We work closely with your design-for-manufacturability (DFM) team to refine concepts, align on requirements, and provide valuable input throughout the entire development and assembly process.

Our wire harness capabilities support a wide range of applications—from standard harness boards to compact, intricate builds used in robotics, as well as rugged assemblies engineered for demanding military environments. Whatever the complexity, our experienced team is equipped to deliver durable, reliable solutions specific to your needs.

Applications for Custom Wire Harness Assembly

While Carr Manufacturing can accommodate any wire harness assembly design for manufacturability requirements, there are certain business sectors that rely more heavily on our services. We currently serve customers in the following critical industries:

Military and Aerospace

Vehicles require specialty cables and wiring that can withstand extreme temperatures, altitudes, and environments. These extra-rugged assemblies are found in aircraft, missiles, spacecraft, military vehicles, and more.

Agriculture

Most heavy farm equipment uses wiring harnesses, including tractors, cultivators, sorters, and balers. We use UV- and chemical-resistant cables with durable fastenings to protect agricultural harnesses from the impact of heavy use and exposure to outdoor elements, ensuring that harnesses work at full capacity all season.

Robotics

Custom wire harness assembly for robotics often presents a complex design for manufacturability and manufacturing challenges. The assemblies are often small and intricate but must still be durable and flexible enough to accommodate the robot’s full, repeated range of motion. At Carr Manufacturing, we possess the precision equipment and experience necessary to create even the most complex wire harnesses.

Oil and Gas

It would be difficult to create an exhaustive list of harness applications in the oil and gas industry: derricks, wells, platforms, and telemetry systems all rely on such assemblies in multiple ways. For these intense applications, we prioritize durability, corrosion resistance, easy installation, and maintenance in our designs for manufacturability.

Telecommunications

The telecommunications industry commissions some of the most rugged harnesses available. These applications require a wire harness assembly that can withstand high loads of data and electricity while standing up to environmental wear. To prevent outages, Carr’s temperature-resistant wiring is encased in NEMA 6P and IP67-rated housing, which provides sturdy protection from dust and moisture.

Transportation

The transportation industry relies on wire harness assembly to power a wide range of vehicles, from cars and trucks to airplanes and trains. Our harnesses are designed for manufacturability to withstand high vibrations, extreme temperatures, and harsh weather conditions, making them the ideal choice for reliable and long-lasting performance in these demanding environments. Our customized designs for manufacturability allow for efficient routing of wires within the vehicle or aircraft, maximizing space and reducing potential damage.

Automotive

Automotive applications present unique challenges, often encompassing miles of wiring that must be installed properly to prevent electrical failures. For this reason, all vehicles, whether consumer, commercial, or industrial, require expert wire cable harness manufacturers with advanced assembly capabilities.

Medical

The medical industry presents multiple wire harness assembly challenges, especially since malfunctions can cause patient injury or even death. Harnesses for electro-medical equipment, irradiation apparatus, and in-vitro diagnostic equipment must be designed for manufacturability for high signal integrity with an emphasis on reliability. Many of the medical harnesses we manufacture use Teflon or silicone for durability and feature specialty safety jacks, bio-sensitive components, and disposable elements.

OEM Manufacturing

Wiring harnesses facilitate many manufacturing processes, including robotic assembly methods and yield enhancement equipment. Specialized harnesses in this industry can protect product quality while also increasing operational efficiency.

Advantages of Wire Harness Assembly

Wire harness assemblies offer clear benefits for a wide range of applications:

- Organization & Space Efficiency – Combines multiple wires into one streamlined unit.

- Reliability & Safety – Protects against heat, vibration, and environmental damage.

- Faster Installation & Maintenance – Pre-assembled and labeled for easy handling.

- Cost Savings – Reduces errors, labor time, and long-term replacement costs.

- Customization – Designed to fit unique industry and performance needs.

Carr Manufacturing harnesses deliver these advantages with precision engineering and quality you can trust.

Carr Manufacturing Company. Your Top Choice Among Cable Harness Companies!

Partner with us! A leader among wire harness assembly companies and discover how our innovative solutions can elevate your project. At Carr Manufacturing, we combine cutting-edge technology with unparalleled craftsmanship to deliver wire harness assembly solutions that meet your exact needs. Contact us today to learn more about our services and see why we’re the go-to choice among wire cable harness manufacturers across various industries. Let’s build something exceptional together!