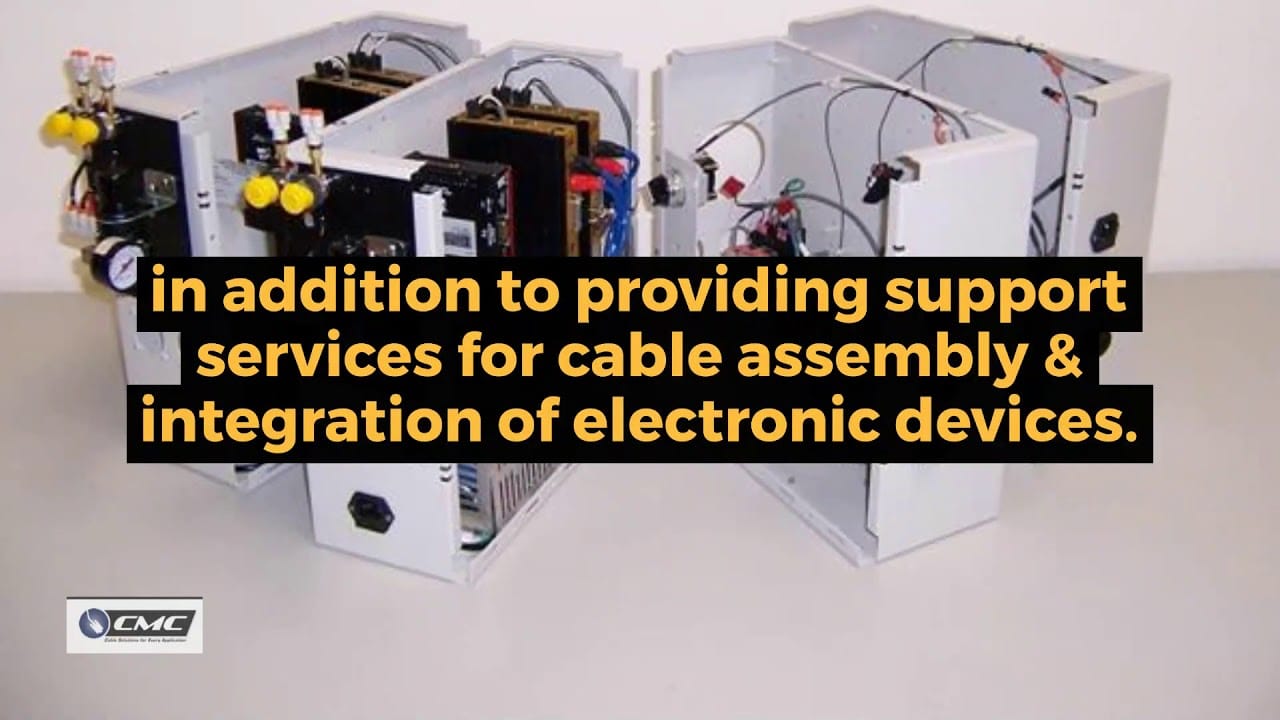

Carr Manufacturing (CMC) is a turnkey electronic manufacturing company that specializes in custom electro-mechanical and box build assemblies. CMC provides Electronic Manufacturing Services (EMS) to help customers achieve the best performance with their circuits. These services are a natural extension of our cable and wire products. We provide support services for cable assembly and integration of electronic devices. This allows customers to benefit from our expertise and quality standards in EMS as well.

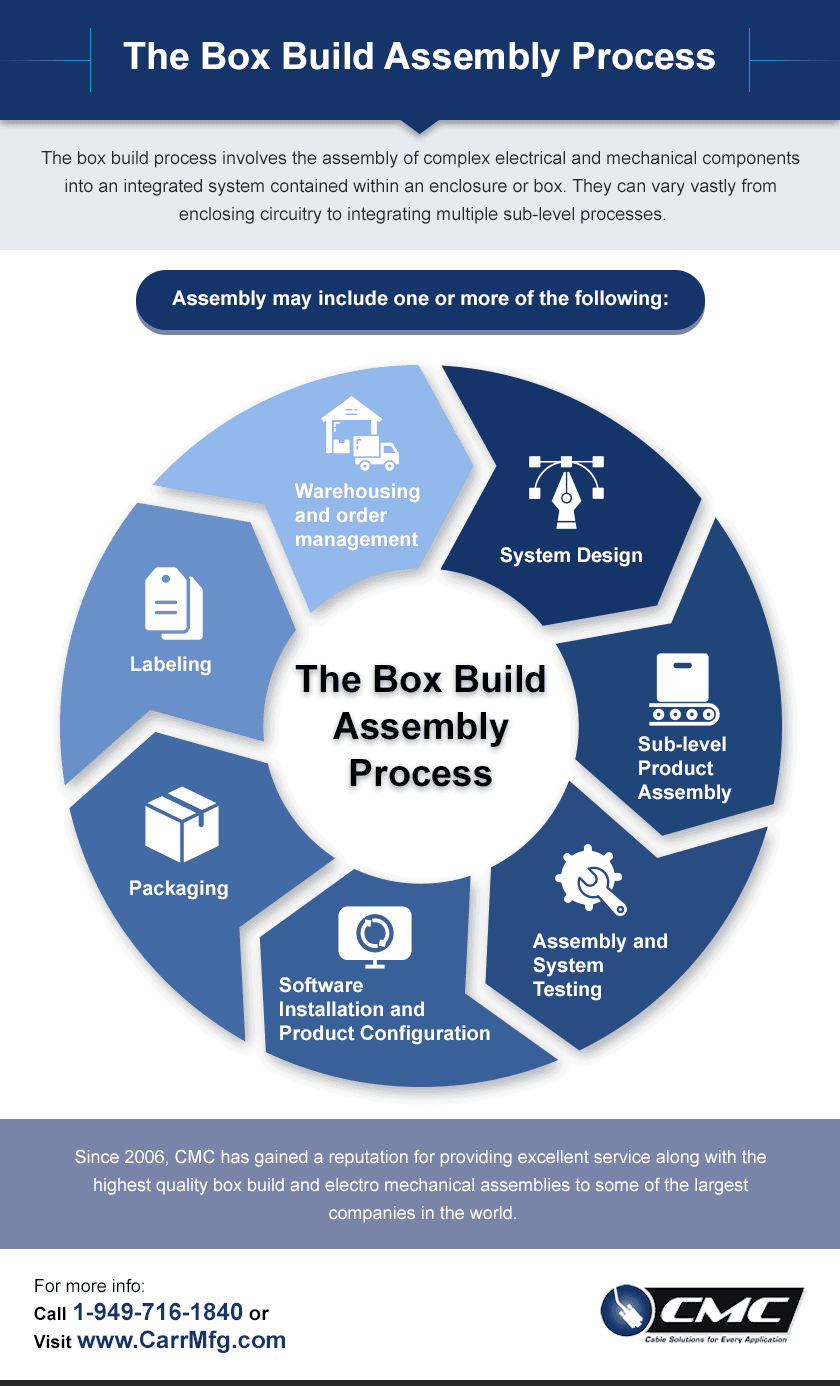

The Box Build Assembly Process

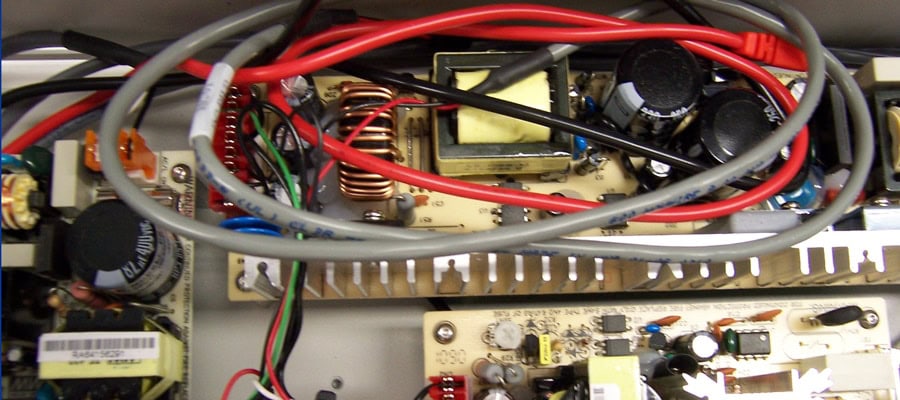

The box build assembly process involves the assembly of complex electrical and mechanical components into an integrated system contained within an enclosure or box. Since each project has its own unique set of requirements, they can vary greatly, from enclosing simple circuitry to integrating multiple interconnected assemblies. Both the industry and application influence the requirements and considerations for wire harness and electro-mechanical assembly projects, and, in turn, the regulations and guidelines that they must conform to.

The box build may incorporate both pneumatic and mechanical components, integration with user interfaces, and more. A customary box build involves installing sub-assemblies and additional components, then wiring and cabling before fabricating the enclosure. Electro-mechanical assembly may include one or more of the following:

- System Design for Manufacturability

- Sub-level product assembly

- Assembly and system testing

- Software installation and product configuration

- Packaging

- Labeling

- Warehousing and order management

The timeline for each build will vary with the level of complexity and the scope of the project. However, there are some steps you can and should take prior to beginning the project. Not only could they shorten the timeline, but they will also ensure you get exactly what you expect from the completed product. Before your box build assembly manufacturers begin work on your order, furnish the following items to help streamline the process.

Bill of Materials

Electronic Manufacturing Services providers require clear expectations of what is to be included in the order. If you are supplying any customer-provided materials, those should be itemized, as well. Consumables such as tie wraps, nuts, bolts, fixatives, wire, wire identifiers, heat shrink, washers, and other small items must also be accounted for, so identifying who will supply them helps prevent delays

Dimensions

Document and provide the expected size and weight of the product to the EMS provider. Understanding the product dimension requirements ahead of time allows the EMS provider to better plan for construction materials. It also impacts the storage needs during the assembly process, as well as the shipping method, materials, and costs. Failing to agree on this ahead of time could result in the unit not fitting the installation site.

Sample Unit/Assembly/Prototype

If you do not have detailed design for manufacturability drawings, or if your drawings are incomplete, providing a sample unit to your EMS provider can be valuable. Skilled providers can quickly build one or more 3D prototypes of your assembly, even without detailed design for manufacturability documents. If your provider is experienced in design-for-manufacturability services, that can be an additional level of assurance that they will be able to translate your requirements successfully into the product you have requested.

Testing

Your provider should explain all the testing they perform before providing a quote. If you have specific testing requirements or if your team must conduct its own set of tests during the assembly process, agreeing on the responsibilities and incorporating those tasks into the project plan avoids delays and miscommunication that could prevent the timely completion of your unit.

Packaging

Electro-mechanical assembly equipment packaging extends beyond the shipping containers. It can be a protective packaging of the fully assembled unit and safeguard its components. Make sure the packaging and labeling services of your EMS provider are clearly stated. If you have specific expectations about packing and transportation, agree on those specs with your provider and document them in the order.

Our Capabilities & Industries Served

Our Capabilities & Industries Served

Since 2006, CMC has gained a reputation for providing excellent service along with the highest quality box build assembly and electro-mechanical assemblies to some of the largest companies in the world. Our ISO 9001 certified facility is also ITAR Compliant and conforms to DFARS 252.225-7001 regulation. The industries we serve, including aerospace, defense, and telecommunications, depend on the innovative design for manufacturability, precision assembly, and rigorous testing that we are known for providing.

Our unique approach to custom box build assembly, combined with our UL-listed assemblies, has allowed us to provide cost-efficient, engineered solutions to virtually any specification. With locations in Southern California and Northern Mexico, we offer faster service and a superior alternative to overseas sourcing.

CMC provides several testing, assembly, and product integration services, which may include:

- Providing components for PCBs

- Fabricating and assembling PCBs

- Providing prototypes or large quantities

- Assembly of power distribution units, cable assemblies, and thermal management units

- Installation of sub-level product assemblies like PCA modules, Daughter Cards, etc.

- Product assembly and configuration

- Packaging, labeling, and barcoding

CMC’s quality electro-mechanical assemblies are used by OEMs as well as various industrial segments, such as the ones given below:

- Aerospace

- Automotive

- Agricultural Equipment

- Computers/Electronic Equipment

- Construction Equipment

- Transportation

- Military

- Energy/Power

- Telecommunications

- Shipbuilding and Transportation

- Medical

Types of Box Build Assemblies

Carr Manufacturing Company supports projects ranging from simple to highly complex assemblies:

- Simple Box Builds – Basic enclosures with wiring and subcomponents for cost-efficient needs.

- Complex Electro-Mechanical Builds – Integration of wiring, PCBs, and mechanical or pneumatic parts with full system testing.

- Ruggedized/Military Builds – Durable assemblies with EMI shielding, heat resistance, and vibration protection for harsh environments.

CMC delivers box build solutions tailored to different performance requirements and industry standards.

Contact Us for Electro Mechanical & Box Build Assemblies & Services

Finding a competitive and reliable electro-mechanical assembly manufacturer can be a challenge. Some of the benefits of choosing CMC for box build assembly and electro-mechanical assemblies include:

- Dedicated Facilities: CMC maintains dedicated facilities for box builds and mechanical assemblies. We also have enhanced material stock facilities separate from our electronic stockroom for material handling of mechanical assemblies.

- Custom Electro-Mechanical Assemblies: We are a 100% customer centric company because we prioritize our client’s requirements. We utilize our in-house cable assembly capabilities to provide custom electro-mechanical assemblies.

- Fast Turnaround: We provide complete box builds and electro-mechanical assemblies with quick turnaround time and strict adherence to quality standards.

- Quality Business Process: We understand that these services are used at a critical juncture in the manufacturing phase. Hence, we employ only the best practices for all our services. Our box builds and electro-mechanical assemblies are manufactured and tested by trained professionals to ensure reliability and long service lives.

- One Stop for Your Wiring and Cabling Needs: CMC is a one stop for all industrial wiring and cable needs. Our product catalogue features industry-grade custom electro-mechanical assemblies to custom wire harnesses and MIL-SPEC cables, which are manufactured to military standards.

To learn more about our box build and electro mechanical assembly services, contact us today.

Our Capabilities & Industries Served

Our Capabilities & Industries Served