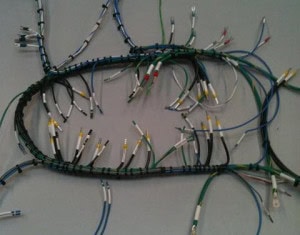

At Carr Mfg. Co., we get a number of first time clients who are interested in getting wire and cable harness assemblies designed for manufacturability for an application. We also get a number of enquiries from customers who are interested in our products, but do not have a lot of information on their design for manufacturability, operation, and benefits.To solve the queries of such customers, we are providing basic information about wire and cable harness assemblies in this post.

Wire Harness and Cable Assembly FAQs :

To ensure that the information is simple and easy to understand, we are providing the information in a question and answer format.

- How many Wires comprise an Assembly? How are the Specifications Decided?

- There is no general number of wires in an assembly. The wires are selected depending on the application and the various systems that the harness will be connected to. A simple system may require a cable assembly with five to seven wires. Larger assemblies may consist of more wires. The cables are selected based on the kind of data that they will be transmitting. The length, insulation material, wire size, and power capacity, are all decided based on the application.

- What are the Benefits of Cable Assemblies?

The following points showcase the benefits of cable assemblies.- Security and Safety: The harness is constructed out of an insulated material. It ensures that the bundle will not flex, reducing the chances of abrasions and short circuiting.

- Simple Installation: Wire harnesses eliminate the need to connect individual wires to their respective systems. Many application systems have existing cable assemblies. Hence, the newly installed wire harness simply needs to be linked with the existing one. Thus, no time is wasted in the wire installation process.

- Reduced Wire Derangement: As the wires are bundles, the assembly reduces chances of wire cluttering. Also, the harness requires less space in terms of installation.

- What is the General Lead Time for Cable Assembly Delivery?

- Every cable manufacturer will offer a different delivery lead time. The delivery depends on a variety of factors, include material availability, production requirements, and inspection time. At Carr Mfg., we can typically deliver your products within two to four weeks.

- What kind of Testing Procedures are Performed for Standard and Custom Assemblies?

- Testing is performed during and after the manufacturing process. As the wire assemblies are being produced, the products and components are continually checked for aspects such as weld peel, overmolding, pull and wire retention forces.

- Other testing procedures performed during and post manufacturing include:

- Leak testing

- Hi-pot testing

- Impact testing

- Connector separation force testing

- Mate and unmate cycle testing

- What types of Cable Assembly Designs for manufacturability are Generally Offered by Manufacturers?

- Cable assemblies can be designed for manufacturability in a variety of ways. Some of the common designs for manufacturability include:

- Point-to-point Assemblies: This consists of terminal strips, which are used to create interconnections between two individual points.

- Multi-Termination Type Assemblies: These consist of multiple fiber cables, which are pre-terminated. This means that connectors are added to each fiber cable before the assembly is created.

- Ribbon Assemblies: Ribbon assemblies are named after the insulated wires, which are connected together to form a flat ribbon. Ribbon assemblies can be subcategorized into high-speed, shielded and jacketed non-PVC, split or multi-branch cable assemblies.

- Radiation Tolerant Designs for manufacturability: These cable assemblies are designed for manufacturability to maintain their performance in applications with high amounts of radiation. Generally, radiation tolerant assemblies have a tolerance range from 5 to 200 Mrad.

- Crush Resistant Designs for manufacturability: These assemblies can withstand immense amounts of pressure. You can find assemblies with the ability to withstand over 250 lbs. per inch.

These are some of the basic questions that first time customers need to know when procuring cable assemblies. Ensure that you have every query answered before you order a product. Clear knowledge of the products, its features and benefits, can help you make a wise decision.